MOD KK1

MOD KK1

Imesa MOD KK1 calandering machine is a cutting-edge model from our K Series laminators, which offers multiple coating solution, multiple lamination and cutting systems, high productivity and efficiency.

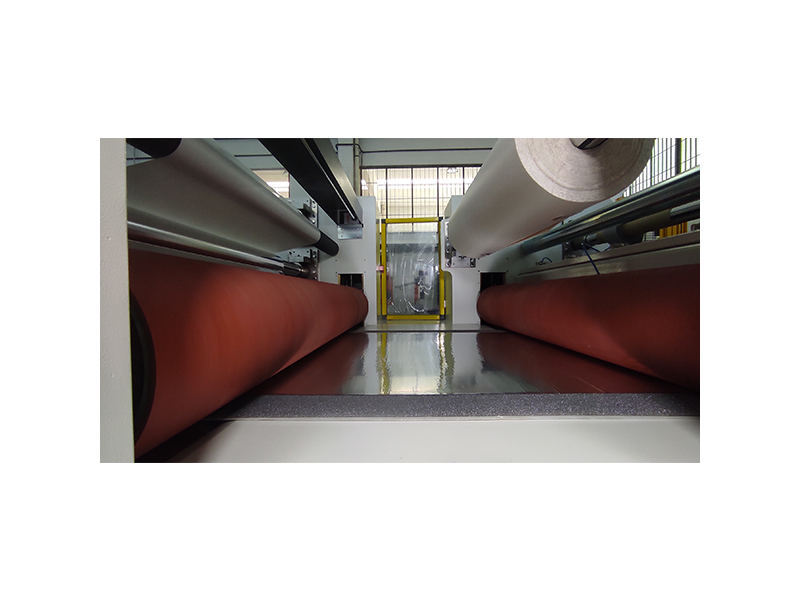

A KK1 calander machine is equipped with a double calandering unit, which is available with standard heating system (with I.R. lamp, adjustable to 80°C-90°C/27°F-32°F) or with diathermic oil heating system (with thermal hot oil heaters, up to 220°C/104°F) to facilitate the glue application during the materials converting process.

KK1 is a flexible calandering solution, that can laminate foam materials with Transfer, PSA and Thermal transfer adhesives, on a single-side or on a double-side.

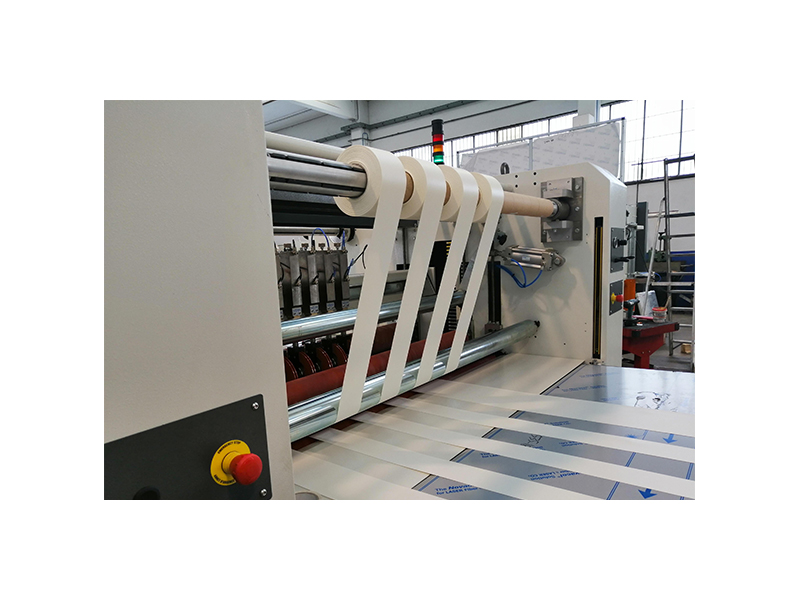

It can be configured with liner remover shafts, complementary unwinders and winders, internal or external, for any kind of processing.

Imesa Mod. KK1 is a customizable laminating machine, that can be equipped for example by the following systems:

- Longitudinal razor blades or crush cutting system;

- Flying cut or cross cutting system with motorised transversal blade;

- Scraps removal systems;

- Automatic material output system;

- Winders featuring independent clutch system.

Possible working modes: Roll-to-Roll, Roll-to-Sheet, Sheet-to-Sheet, Sheet-to-Roll.

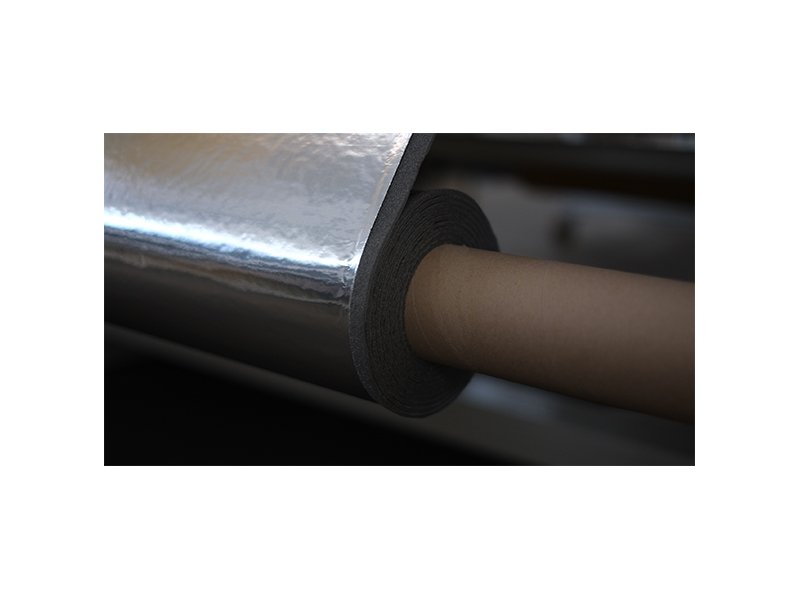

- Laminator machine with heatable rollers and integrated cutting system

- Device to check for material “curling effect”

- Electronically adjustable speed max 20 m/min

- Roller temperature heated to 90° C or 230° C

- Available for material widths from 1600 mm to 2100 mm

- Calender to convey the material (puller)