Omac Leather Preparation & Finishing

The all round service, providing the cutting solution for the soft cutting industries

We are pleased to be working in partnership with OMAC of Italy, and we are able to supply their complete range of machines and systems as well as after sales service and spare parts, we specialise in the machines and systems immediately allied to our core industry of leather bags, belts and shoes.

Some of the best selling ranges in the UK are listed below. Please Contact Us if you require information on the rest of the Machinery Ranges;

Belt & Edge Dyeing

SHUTTLE is an automatic patented dyeing machine used in belts and leathergoods. It is able to dye perfectly the belt tips and edges or straps (also not straight) at the same operation, thanks to the patented mechanism of coloring.

Main features:

• Transport carried by bottom roller with upper free roller;

• Color distribution automatically on inking wheels;

• Automatic double variable speed for tips and edges;

• Lateral color container holder;

• Working width from 18/20 to 80/85 mm.

OPTIONAL: Stand

The 990N are machines adapted to colour the edges in horizontal of any kind of material, leather, synthetic one, cardboard, etc. with a painter roller of 16 mm diameter.

Equipment: 2 shaped rollers (‘L’ with grooves).

Characteristics: Motor with one speed and guides (up/down).

Models available:

- 990N MINI Horizontal Mini edge dyeing with a painter roller ofdiameter of 7 mm.

- 990TE Horizontal edge dyeing with extractable little head with painter roller of diameter of 16 mm.

- 990TE V Horizontal edge dyeing with extractable little head, speed variator and painter roller diameter of 16 mm.

- 990 V Horizontal edge dyeing with speed variator and with painter roller of diameter of 16 mm.

Drying Tunnels

Horizontal drying tunnel with variable speed and temperature adjustable up to 110° C. Drying tunnel 1500 x 250 mm.

Plane length 2700 mm.

Multifunction adapted drying machine for bags, suitecases and all kinds of materials used in leather and shoes production, ecc.

Main features:

- Electronic air control and transport speed tape;

- Automatic opening of windows of entrance and going out of goods;

- Direct checking of material during drying;

- Easy positioning by self blocking wheels;

- Maximum heat 110°;

- Maximum resistance power of heating 4000 Watt;

- Total absorption 4200 Watt.

Models available :

- E130 S Horizontal drying tunnel with variable speed and temperature adjustable up to 110°c. Drying tunnel 1500 x 250 mm. Plane length 3900 mm.

- E130 SS Horizontal drying tunnel with variable speed and temperature adjustable up to 110°c. Drying tunnel 1500 x 250 mm. Plane length 4900 mm.

Versioni Applicabili:

- BACK 1 Conveyor, adjustable height and grades, applicable to driers “E 130/150”. length 3000 mm.

- BACK 2 Conveyor, adjustable height and grades, applicable to driers “E 130/150”. length 4000 mm.

- BACK 3 Conveyor, adjustable height and grades, applicable to driers “E 130/150”. Length 5000 mm.

OPTIONAL: control device falling material.

The drying tunnel E3000S is a suitable machine to dry the belts, shoulder straps and small leather pieces. It has speed variator, adjustable temperature up to 140°C and adjustable airflow through the tunnel.

Drying tunnel 2640 x 80 mm.

Main features

- Almost Silent Operation;

- Heating and speed electronically controlled to suit any type of material and colour;

- 2 heating elements of 2000 watts each for uniform and continuous heating;

- Drying tunnel easy to inspect fitted with an insulated plate cover;

- Easy installation and positioning thanks to four self-locking wheels.

Total absorption about 4200 Watt. Productivity 10/15 mt./min.

Belt Edge Polishing

Brushing machines 845 are used in leather goods field to polish edges of belts, shoulder straps, leather or synthetic strips etc.

This horizontal brushing machine has 4 brushes with vertical transport complete of speed variator for brushes and transport, vacuum system and tip brushing device “SP 100”.

Main features:

- Brushes are interchangeable and adjustable up/down by manual knob;

- Speed variator from 2.000 to 4.000 revolution/min controlled by “Inverter”;

- Vacuum system for dust;

- Working width is adjustable from mm. 8 to mm. 80 in one operation;

- Voltage 220 single phase 50/hrz;

- SP100 = Tip brushing device with vacuum system

Belt Edge Shaping & Trimming

Multi-functional machines suitable for matching, trimming, rounding, polishing belts and shoulder straps.

The width of the belt can be from 20 to 50 mm. and the amount of material to be removed is easily adjusted by lateral knobs without the replacement of any piece.

Equipment:

- “U” shaped blades;

- Speed variator;

- Aspirator system;

- SP100 Tips` brush;

- Equipped with matching-trimming device Kit and 4 brushes.

OPTIONAL: AF20 blades sharpening device.

Foil Embossing

The printer 730/300 SN is used in leather goods to make: logo, lettering and numbering both hot, both high pressure. The machine is equipped with an automatic device which carries the roll of colored paper (gold, silver, etc..) Up to a maximum width of 140 mm; and alsoa pneumatic device that pulls the carriage of support for punch.

Mechanical Roller Embossing for Belts

Also Available in Hydraulic Version

The STM10 is a mechanical pressure calender used in leather and garment industries to emboss (hot or cold embossing) different details on belts, leather stripes, etc.

Mechanical roller embossing machine for belts with the change of the upper and lower roller by release, speed variator and adjustabe variator (roller marker drawing of your choice).

Characteristics:

- Mechanical function;

- Heated upper roller;

- Speed variator with inverter;

- Fast roller changing system;

- Mechanical lowering of upper roller;

- Electronic thermoregulator;

- Safety devices conforming to CE standards.

Electrical data:

- Single phase 230V;

- Absorption 3,0 A;

- Power 0,75 Kw.

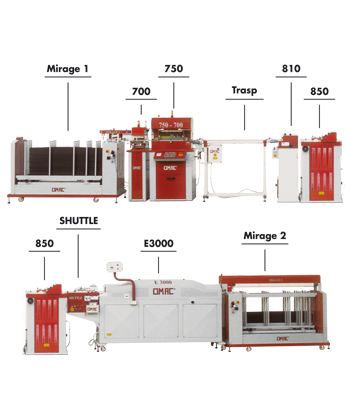

Automatic Production Lines

These can be assembled in modules combining with models such as the Edge Dyeing E3000

GF automatic drying tunnel with continuous rotation, with 2 trolleys+ 10 trays for leather goods and footwear materials.

Working plane 2700 mm.

Drier tunnel 1500 x 450 mm.

Main features:

- Variable tunnel dimensions: 500x450x1500;

- Variable speed of conveyor belt and electronic control temperature up to max 110°C (heat elements absorption 4000 Watt);

- Two easy moveable and interchangeable trolleys for loading and unloading of material, complete of 10 steel trays;

- Multi-functional command panel to select five working mode, automatic or by pedal;

- Possibility of working line introduction of continous cycle;

- Easy moving by wheels.

MODELS AVAILABLE:

- GF 150 – 1 Drier with continous rotation, with 2 trolleys + 10 trays. Plane lenght 2700 mm. Drying tunnel 1500 x 450 mm.;

- GF150 – 2 Drier with continuos rotation, with 2 trolleys + 10 trays. Plane lenght 3600 mm. Drier tunnel 1500 x 450 mm;

- GF 150 – 3 Drier with continuos rotation with 2 trolleys + 10 trays. Plane lenght 4100 mm. Drier tunnel 1500 x 450 mm.

OPTIONAL:

– additional trolley;

– triangle stand.

Automatic Loader & Unloaders

Continuous research by OMAC of new technologies, always striving to satisfy our customer’s demand, has allowed for the development of new machines. These machines can connected together to form a single production line allowing for higher quality products with less time and energy consumption. Each line can be composed according to your requirements and working material.

Here you are below the composition of DELTA A:

- Loader MIRAGE 1

- Punching-numbering 750/700

- Conveyor TRASP

- Edge trimming 810

- Polishing/brushing 850

- Coloring machine SHUTTLE

- Drier E 3000S

- Discharger MIRAGE 2

Above are some of the best selling ranges in the UK for more information on any of these please Contact Us