CHIESA AUTOMATIC CNC CUTTING PRESS

Chiesa Automatic CNC Cutting Press

Historically ATOM have built CNC traveling head machines from 25 to 50 tons for over 25 yrs, but now as well as keeping their existing Series 5 range ATOM have teamed up with Chiesa of Italy to offer an even greater range of CNC cutting machines. This allows a better choice for you, the customer whilst keeping Italian and European build quality, Chiesa also offers the patented ‘No Hydraulics’ system. This uses a really rather large Ballscrew to drive the cutting head down, this means the machine is quieter, quicker, and importantly with regards to the cutting belt… more accurate.v

CNC Application Videos

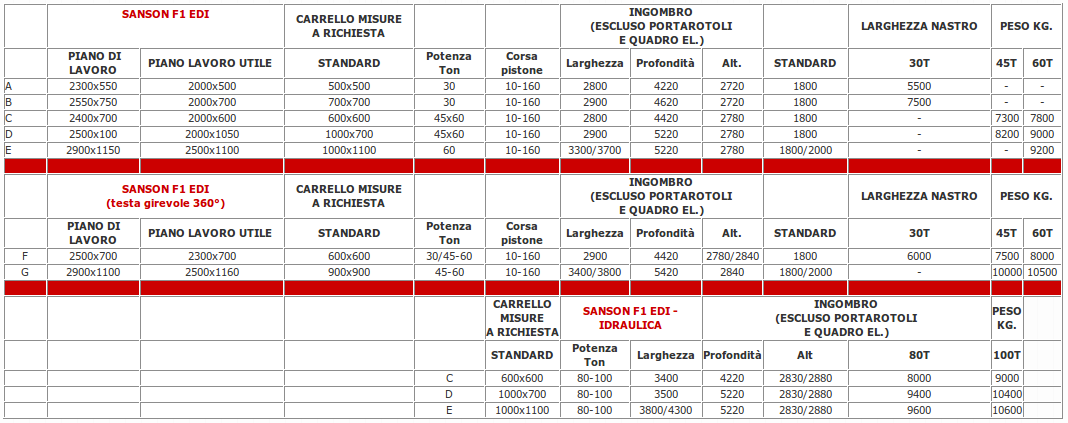

Chiesa Sanson F1 EDI

SANSON F1 EDI

FUNCTIONAL FEATURES “NESTING” CHIESA CAD The F.1 cutting press features an optional CAD-OPTIMISER designed to improve the placement of the cutting die on the material to be cut. A rapid system that is simple and easy to use obtains the cutting die’s exact geometry directly from the mounting plate, detecting eventual dephasing of the baricenter or by DXF…

F1EDI

THE SANSON F1 EDI IS THE FIRST PATENTED ELECTRICALLY DRIVEN AUTOMATIC CUTTING PRESS (NO HYDRAULICS)

• Greater control over die-cutting operations

• Possibility of optimising cutting in relation to materials and type of die-cutting tool used

• Reduction of direct costs by 50%

• The cutting press absorbs electrical power only at the moment of punching

• Reduced noise emissions

• Less maintenance on installation

• Reduced overall dimensions

• Improved reliability and cycle repeatability

• Increased respect for the environment

• Integrated cutting press control software, with easy to use graphic interface

• Cutting controlled simply by setting the height of the die-cutter.

CLAMPING FEEDER

The best cutting system is the one which gives the fastest working and largest saving in materials which depends not only on the shearing machine itself but also on the system feeding the machine. The clamping feeder has been carefully developed for both multiple strata materials and single materials, allowing a speed and a feeding accuracy that are twice that of traditional feed rollers systems; reducing the waste material to a minimum.

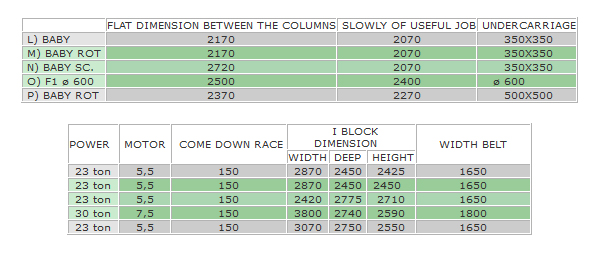

Chiesa Sanson F1 Baby EDI

STRUCTURE

Constructed in fully welded steel, built for strength with a computer designed triangulated structure in order to guarantee maximum rigidity and reliability.

UNDERCARRIAGE

In welded sheet with the main piston built-in steel. It slides using a ballscrew system to reduce vibration and noise and improve longevity.

MOVEMENT UNDERCARRIAGE

Using a Reinforced toothed pulley belt to move the two CNC axes, giving you a longer life, requiring less maintenance and better repeat positional accuracy even when running at higher speeds.

F1EDI Automatic Belt Cutting System SANSON F1 BABY

The cutting belt on this kind of Die Cutting system is probably the most overlooked item, but its quality is essential to the maximum operation of the system in the following key ways:

Advance of the material to give perfect alignment to the die cutters

Support of the Die Cut, minimising the risk of material jams

To transport the cut pieces to the operator or to the automatic unloading system

Optionally we offer a sophisticated system of directly managed mechanical operation via a computer interface, which automatically controls the Die Cutting head giving extreme cutting precision and reduced damage to the cutting belt.

Having built this kind of Die Cutter and Cutting Belt for more than 20 years we have customers who, using our CNC systems have belts lasting in excess 8 years (based on indicative 2000 hours a production run)

Particular attention has been given to the belt, so that it can be replaced in approximately an hour, without having to take apart the machine or having to allow extra space around the machine to complete the exchange. Since this kind of machine is used in multiple fields of the industry there are a range of belt types each built to a high tolerance to maximise production on all material types.

Chiesa Sanson F1 'Look and Cut'

SANSON F1 “LOOK AND CUT” is the first automatic cutting press for leather with complicated shape dies.

Designed for the very fast cutting of materials with irregular features such as leathers that require multi-punch dies.

Equipped with a die exchange PIT-STOP with spaces for 14 tools. Independent work stationing. Cutting power tons 25. Movable sight system: where the system measures the material perimeter.

NESTING software optimises the layout and use of material automatically by using the outline dimensions it measures. All work phases are automatic. The operations are visualised in real time on central monitor. Integrated cut control software, graphical interface for ease of use.

Chiesa Sanson F1 'Look and Cut'

Not all materials are suitable for die-cutting, some, such as metallic or extremely rigid materials, must be cut with a “male/female” mould thus obtaining a greater precision of the cut pieces.

This machine, which combines all the performance of the Sanson F1 with an extremely precise, custom-built system designed to meet and exceed today’s demands and those of the future. With power availability from 25 tons on up to 100 tons, the advantage of this is technology is that, unlike normal presses, it is not necessary to pre-cut the material giving you considerable savings on processing times.

Chiesa does not have any pre-set specifications as they believe if you are investing in a machine of this build quality and long service life it should be exactly what you want, call or email Paul today and ask what tonnage and size head again cutting bed you would like

Do you need a new Cutting Belt for the range of machines? Then please visit our Cutting Belts page.

Cutting Systems UK recently installed a pair of Chiesa 40ton, 700mm x 700mm Sanson F1 EDI.

‘We are proud of what we do, working with the customer to precisely determine their requirements now and for the future and then offering the ideal solution’ Gareth Howe carried on to confirm that ‘All the delivery, installation, setup, and full onsite training was carried out by us. We even do the preventative maintenance to keep the machines working at peak efficiency now and into the future’

For more information on the Chiesa Sanson range of machines give us a call on 01933 359359 or CLICK HERE to send us an email.

Remote Connection Aftersales Support

We now offer Remote Connection support for our range of Chiesa CNC Cutting systems. This works by us accessing your machinery via a secure remote link and can very quickly identify if is something that we can fix along with you or if it needs an engineer's visit. This is made possible as we can link into the PLC as well as the base software files allowing for a much quicker assessment than normally possible over the telephone with factory floor staff.

For more information on this service Click Here