Laminator Machines

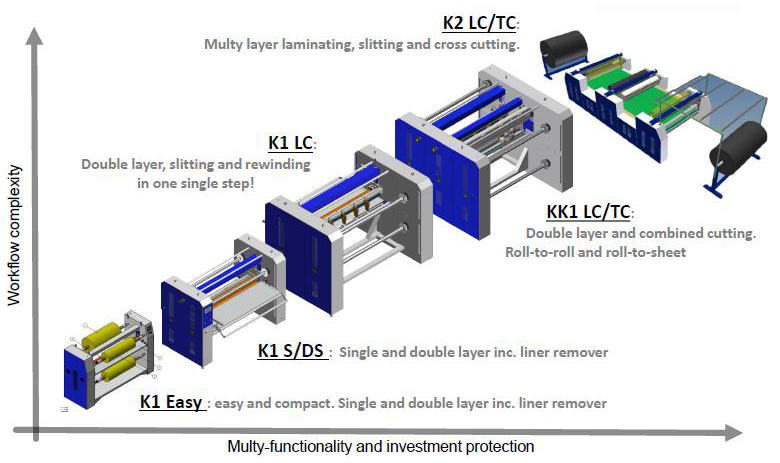

Imesa Laminator Machines are designed to adhesive and laminate flexible materials generally with Transfer Film, Pressure Sensitive Adhesive and Thermo adhesives.

Depending on the chosen models and configurations, Imesa calanders can process expanded materials, rubber and its derivatives, adhesives and double-sided adhesives (including acrylics), fabrics, non-woven fabrics, natural and composite fibers, aluminum.

Adhesives, Insulators, Flooring and Roofing (both Building and Automotive), Medical, Clothing are just some of the areas where they are applied.

Imesa laminator machines can be designed and configured according to our customers’ production needs in order to allow the automation of processes respecting the high quality of the final product with maximum versatility.

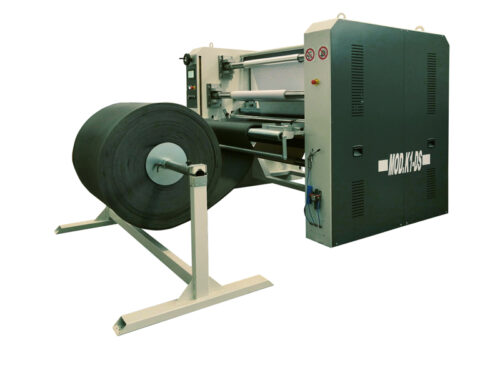

“Entry Level” laminator machine, to laminate with PSA and Transfer adhesives, equipped with clutch motor driven by a foot control.

Laminator machine designed to laminate flexible or foam material on one side or both, with PSA or Transfer.

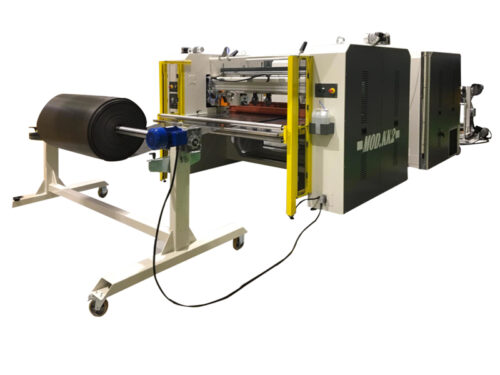

Laminator machine designed to laminate sheets, with PSA, Transfer or Thermo adhesives, on one side or both. Available with integrated slitting and cross-cutting systems, and standard calender or diathermic oil rollers.

Laminator machine designed to laminate with Hot-Melt glue. Available with integrated slitting and cross cutting system, and automatic systems for material input and output.