Flexcut Flash Series

The FlexCut series represents the evolution of the previous Flashcut Series of machines. Its solid structure, high quality components and state-of-the-art CNC control system give you maximum reliability combined with a huge material range capability and accuracy. Available in either Static or Conveyorised (Belt Feed) versions with a wide range of configurations and available accessories make these new systems a flexible tool perfect to satisfy any cutting requirement.

The FlexCut series and before it the FlashCut models are the UK's most popular, in Cutting Systems UK core industry, gasket manufacture. Where accuracy, strength and reliability are everything.

Famed amongst the biggest cutters and manufacturers for brute strength and dimensional accuracy.

The FlexCut range is available with cutting areas from 1500mm x 1500mm right up to 6000mm x 1500mm, all with options such as high daylight for foam cutting industries, conveyorised cutting for 'off the roll' automatic cutting (like our CNC die cutting presses) cycles such as the felt industry and EMHD for milling and cutting processes like foam tool box inserts and PTFE gaskets. ATOM's internationally and industry leading projection system is available as an option on all models, great for cutting leather where each one is different, or using up offcuts in the gasket industry.

Below are our most popular sizes and combinations in the UK, but really because of the modular build style we have endless combinations available.

Three different cutting tools cartridges are available, fixed blade, electrical oscillating and pneumatic oscillating. A customer can have one, any two or all three depending on the range of materials you maybe cutting.

Fixed Blade Chuck: this ideal for thinner rigid materials such as shim gaskets, or 'soft sealing' materials such as expanded PTFE's where shape and edge finish are critical. Also quieter and faster in many applications then the other two options.

Electrical Oscillating Chuck: ideal for soft thinner leathers in shoe manufacture and greasy leathers such as buffalo, their production environments where the brute strength of the air chuck (below) is both too noisy and not needed. Gaskets cutting can also be achieved as the blade speed is slower meaning materials such as rubber will not rebond under the heat caused by blade friction.

Pneumatic Chuck: although this requires a lot of air (see our dedicated range of compressors), this chuck is simply a brute of a tool, suiting heavy leather production and heavy gasket this tool will cut through tanged graphite and CNAF with ease. It is Cutting Systems UK favourite tool, it will cut just about anything you care to put on the machine, it is reliable and easy serviced.

Flexcut 1515s

Cutting Systems UK second most popular seller in the FlexCut series, with a 1500mm sq cutting area this is ideal for the gasket cutting industry, allowing the accurate cutting of materials such as tanged graphite and mica materials due to the standard sheet sizes these are produced in.

Also very popular in small gasket cutting workshops around ports and industrial areas for companies offering 'walk-in trade counter' service where low quantity, high quality and accuracy are all a must.

The robust five tool cutting head allows the processing of material up to 14mm in thickness, with knife, two punches and pen (also pricker for leather cutters).

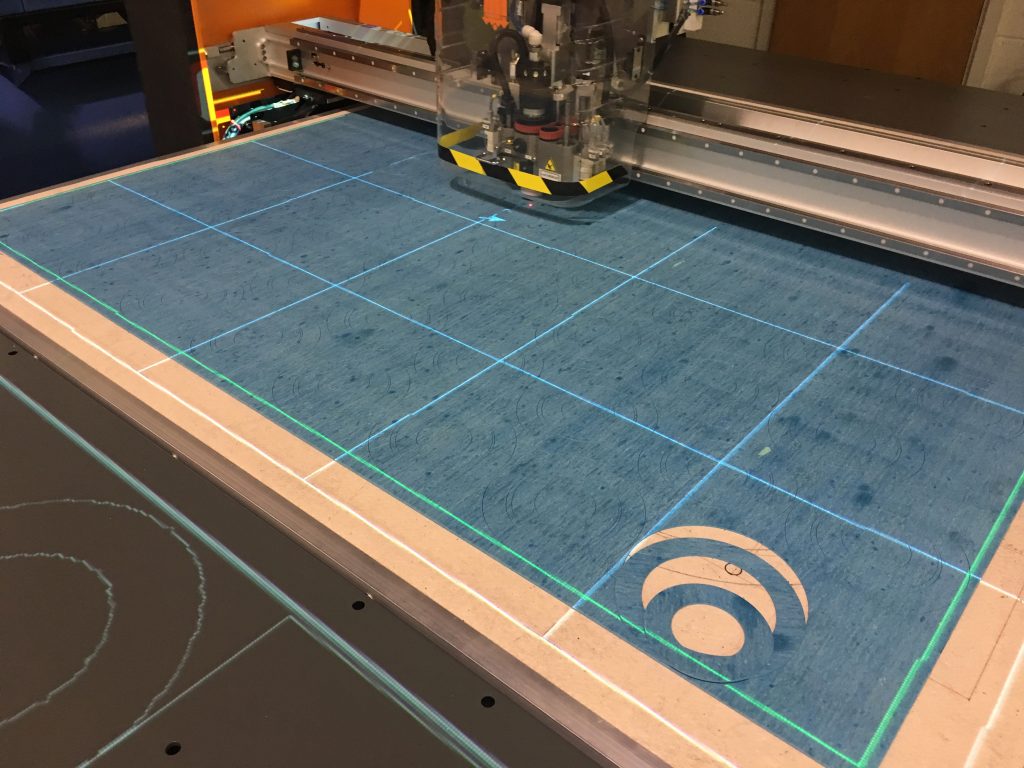

A recent installation by Cutting Systems of a FlexCut 1515s with projection system in a 'walk in' port based gasket cutter, shown above cutting CNAF gasket material..... 'the ATOM's bread & butter' and below cutting tanged graphite based heat exchanger gaskets

FlexCut 3015s

Possibly the most versatile machine ATOM offer, certainly our biggest selling knife system in the UK. Its 3000mm x 1500mm cutting area makes it appealing to leather and gasket cutters, ideal for many synthetic materials due to their standard sheet size suiting this bed, and with the HD models popular in the foam cutting sectors too.

Many gasket cutting companies have several of these machines as they allow both the cutting of complete sheets giving good nesting and material usage, and also larger shapes such as inspection hatch and tank gaskets.

The model allows double end working, whether it be in the leather industry or the gasket industry, the machine can be cutting in one half/ side of the bed whilst the operator is unloading, reloading and nesting in the other. When cutting of side 1 has finished the machine will move over and continue with side 2 automatically, great for tea breaks and lunch time. Both sides can be set for different materials and different feed speeds etc meaning multiple jobs can be processed by one operator on one machine, in effect one man working two machines.

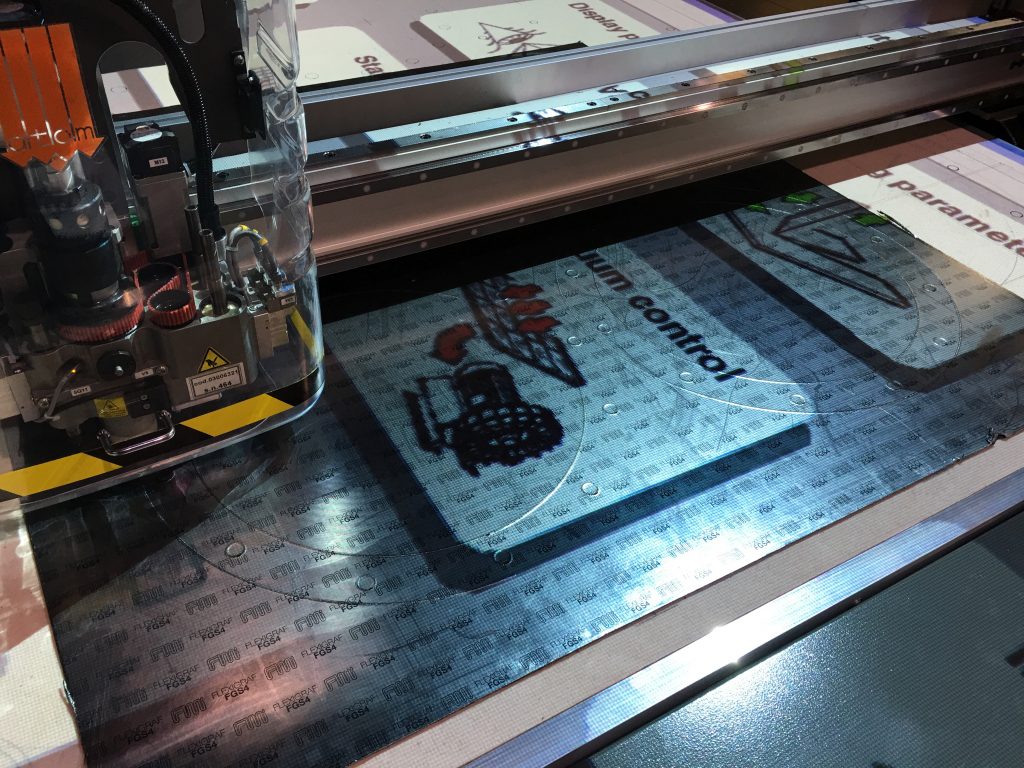

A recent UK installation into a leather bag manufacturer, this 3015s is 'Cutting Systems UK Standard Spec', with the five tool head and projection system allowing two different sized punches on any one shape. A pen is also utilised as well as the knife, in this case an electrical chuck was used as the leather could be could quickly and efficiently this was. Cutting Systems also supplied and service the compressed air system pictured in the background.

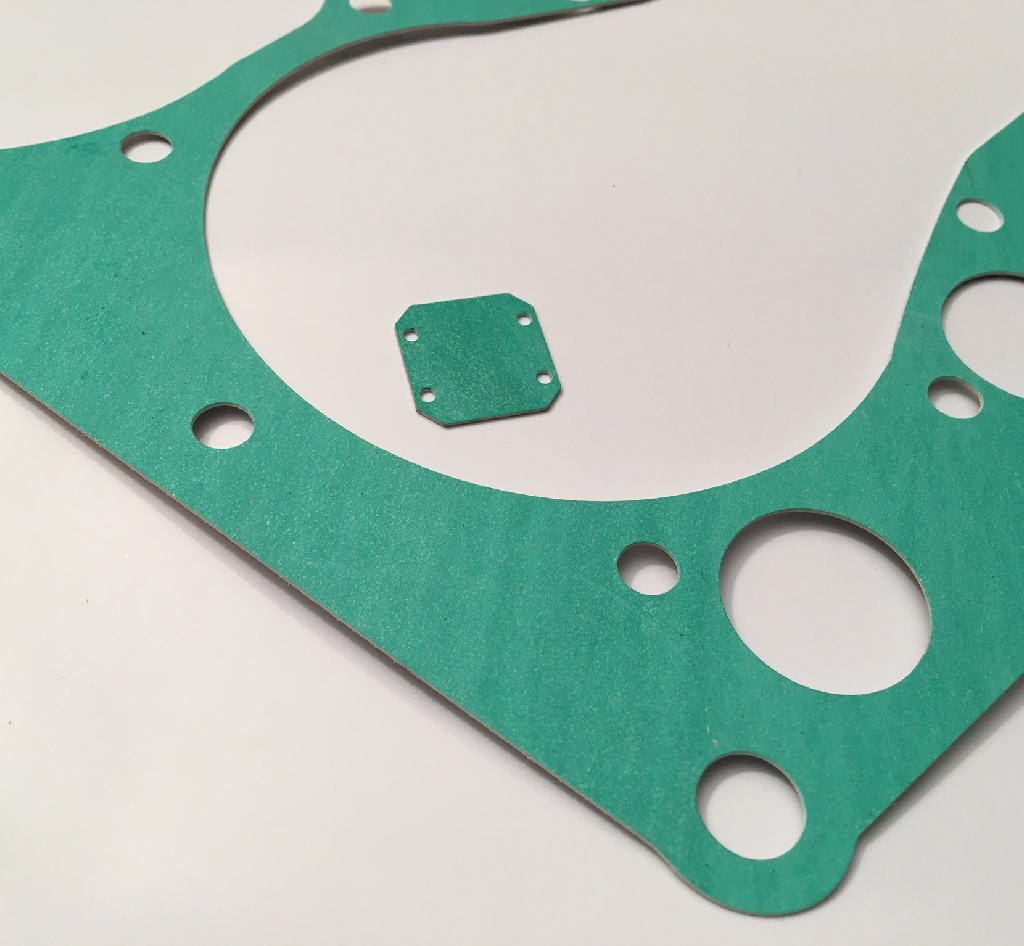

Cutting Systems own engineers setup and trim the machines into the industry we install the machine into, to ensure the best speed and accuracy balance is found. After 15years in the gasket industry our engineers understand what is required by different cutters and different industries from pipe standards to aerospace. This sample cut from 1mm CNAF using an ATOM FlashCut and setup by a Cutting Systems engineer.

Flexcut 3020s

A bigger version of what makes the above two models so good but this machine is larger at 3000mm x 2000mm meaning that many different sheet variations can be turned by 90degrees and therefore two sheets of CNAF gasket material for example can be loaded at once. This means better nesting and material usage, also the machine can be left working on large gaskets or large orders whilst the operator busies themselves with other tasks, or even operate another ATOM knife table.

Many large producers will have multiple machines, we have UK customers with up to eight ATOM knife cutting tables. They will have one 1515s for cutting 'dirty' materials such as tanged graphite and mica, suiting the material size and stops cross contamination. They will have several 'all-rounders', the 3015s and then one 'big one', a 3020s, for cutting large gaskets in diameter or rectangular and also for cutting multiple complete sheets at once for example cutting large quantities of standard gaskets IBC and full face.

Case Study

Installed in 2017 by Cutting Systems UK at Irelands largest gasket manufacturer this FlexCut 3020s (above) has proved the ultimate cutting machine, no matter what material is thrown at it the machine will cut it. Allowing not only national service but local walk in service too. Shown with 1500mm diameter full face gaskets being projected down onto the bed ready to cut.

This installation was featured in a case study, click here to read more.

Tool Head Options

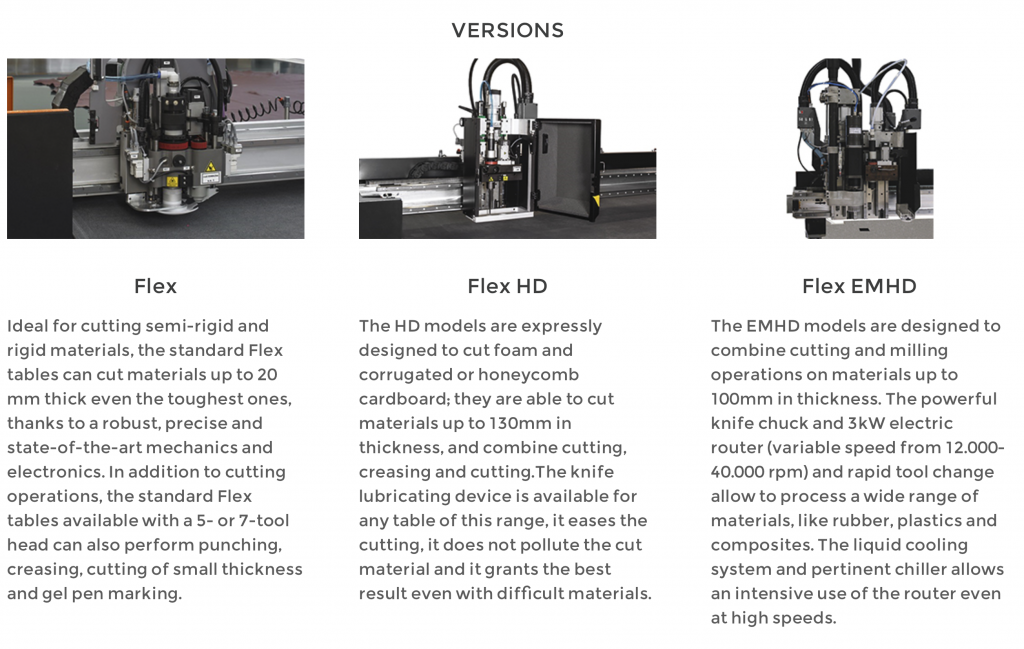

A brief and simple over view of the most common head options for the FlashCut Flex and how they equate...

For the cutting of leather and gasket then the FlashCut’s five tool head is the way to go, out personal favourite is this tool head, for its robustness and reliability, for added versatility we can build this head with additional vertical stroke meaning thicker material on the standard FlashCut can be accurately cut. Its design has not changed in just about all 15years it has been in production, and its brute strength allows the machine to get through most heavy materials whilst keeping dimensional accuracy and finish. It is best for high quantity cutting too.

If cutting foams or laminated foams then either the HD or the EMHD is best, the EMHD allows you to mill out foams as well as having the knife for cutting, so the shape can have the two very different processes completed in one movement by one machine and using one shape file.

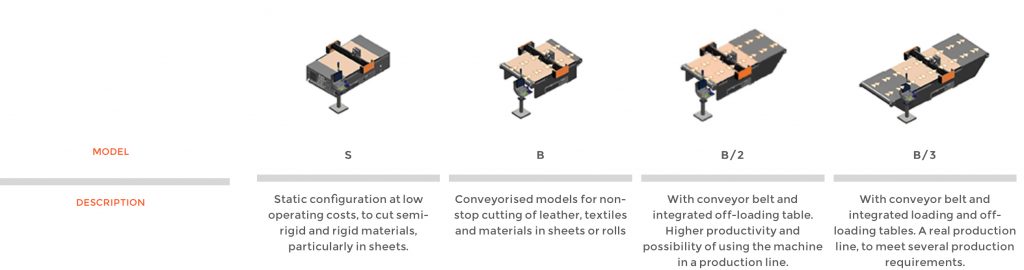

Machine Type

for industries such as traditional gasket cutting and leather, then the 'S' series is the most suitable.

If cutting from the roll, such as rubber, paper gasket or felt then a 'B' model may be best... (and we personally recommend the B2, to give you a good chance to keep up with the machine and have an area to pick and unload from whilst the machine keeps cutting)

There are many options available for the Flash Cut Systems please for more information Contact Us to discuss your individual requirements, we will be more than happy to help you choose the right machine for your application.